Guava pulp making machine is a highly efficient pulping equipment designed for guava, pineapple, kiwi and other fruits, and is widely used in food processing fields such as juice, jam, and puree. This machine uses a rotating screen and scraper structure to break the raw materials, remove the core, and automatically separate the pulp and residue, significantly improving production efficiency and finished product quality.

This guava pulp making machine is suitable for processing guava, pineapple, kiwi, and other fruits with seeds or need to separate pulp and pomace.

Guava Fruit Pulping Machine Features:

- Automatic pulp and residue separation: During the pulping process, the juice and the residue are automatically separated, reducing manual intervention, improving efficiency and hygiene.

- Can be used alone or online: This guava fruit pulping machine can be flexibly used in automated processing production lines, and is also suitable for independent stand-alone operation to meet different processing scenarios.

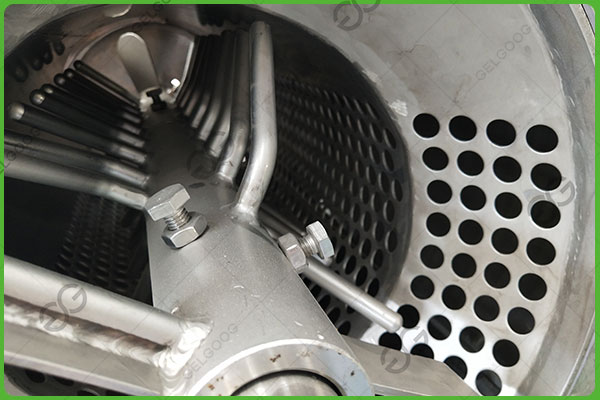

- Hygienic material design: All parts in contact with the guava are made of 304 food-grade stainless steel to ensure production safety and meet food processing hygiene standards.

- Compact structure and easy maintenance: The machine has a reasonable structure design, simple operation, convenient maintenance, and reduces the cost of use.

- Processing capacity: 0.5-4 tons/hour, non-standard customization can be made according to customer production capacity requirements.

Services from Guava Pulp Making Machine Manufacturer:

- Equipment customization service: parameters such as screen aperture and rotation speed can be adjusted according to material characteristics.

- Whole line supporting solutions: Provide a complete set of guava pulp production line design and supporting equipment selection from cleaning, sorting, pulping, filling, sterilization, etc. Can assist customers in building the whole plant layout, improve the level of automation and production efficiency.

- Installation, commissioning and training: Send experienced technical engineers to the customer site for equipment installation and commissioning. Provide systematic training for operators to ensure proficiency in operating procedures and daily maintenance methods.

Reviews

There are no reviews yet.