Strawberry jam and blueberry jam are two common jam products, widely used in bread, pastries, desserts, yogurt, and beverage flavoring. The production of these two fruit jams requires specialized equipment, but because the production process for both jams is essentially the same, the blueberry& strawberry jam production lines used are also the same.

The overall production process for strawberry and blueberry jam includes: raw material selection and cleaning, pulping, mixing and heating, vacuum concentration, sterilization, filling, and packaging. However, due to the different forms, textures, and moisture content of the raw materials, some steps may vary.

Blueberry And Strawberry Jam Production Process:

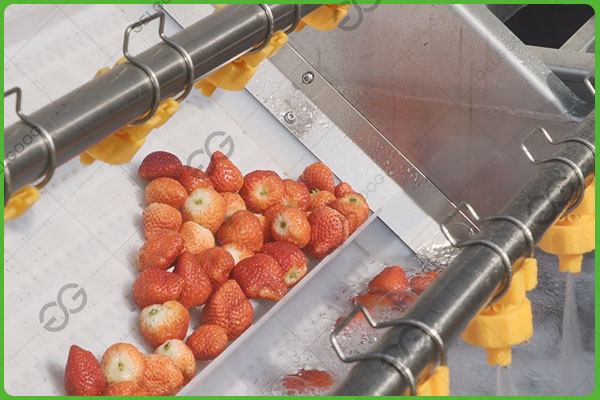

1. Sorting and Cleaning

Both strawberries and blueberries are sorted manually or mechanically upon arrival to the factory to remove unripe, rotten, or pest-infested fruits. A bubble washing machine combined with a spray system is then used to thoroughly clean the surface of the blueberry and strawberry without damaging the skin.

2. Pulping

The blueberry&strawberry pulping machine crushes blueberries and strawberries and removes insoluble matter such as stems and seeds, resulting in a smooth, even puree.

3. Ingredients and Heat Mixing

Add sugar and pectin to the blueberry or strawberry pulp and heat mix. Heating not only helps dissolve the sugar and pectin but also promotes the reaction between the pectin and the fruit acid to form a stable gel structure.

4. Vacuum Concentration

Using vacuum concentrators to evaporate water at a relatively low temperature preserves the jam’s color and aroma while achieving the desired solids content (generally 60%-68%). However, blueberry puree naturally has a lower water content, so the concentration time is relatively short. Strawberry puree has a higher water content, so the concentration time is slightly longer, and care must be taken to prevent excessive color darkening and loss of aroma.

5. Pasteurization

This step utilizes pasteurization technology to ensure the product’s microbial safety while preserving flavor and nutrients.

6. Filling and Packaging

The sterilized jam is hot-filled or cold-filled under aseptic conditions, and bottled in glass or plastic bottles, depending on the needs. After filling, the jam is cooled, labeled, and packaged.

Blueberry Jam Making Machine:

We offer complete strawberry and blueberry jam production lines, from raw material processing to finished product packaging. We can customize designs based on your production needs, plant layout, and budget. Key advantages include:

- High level of automation: The blueberry jam making machine utilizes a plc control system for automated cleaning, temperature control, and concentration time setting, reducing manual operations and errors.

- Energy saving and quality assurance: The vacuum concentration and temperature-controlled sterilization process effectively reduces energy consumption while ensuring the color, flavor, and nutritional value of the jam.

- After-sales and technical support: We provide installation and commissioning, operator training, recipe optimization, and ongoing maintenance services to ensure stable and efficient production.

Whether you’re a small or medium-sized business or a large processing plant, our blueberry jam & strawberry jam production lines can help you achieve efficient, consistent jam production. Our equipment provides a solid foundation for your market expansion.

Reviews

There are no reviews yet.