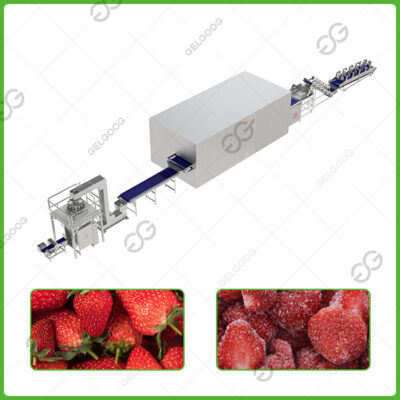

Freeze-dried strawberries are made from fresh strawberries through freeze dried machine. They retain the original color, aroma, nutrients and shape of strawberries and are loved by many consumers.

Principle of Freeze Dry Machine for Strawberries:

The strawberry freeze dried machine uses the sublimation drying principle. At low temperatures, the moisture in the strawberries exists in the form of ice. This process is accomplished by directly sublimating the ice into water vapor and discharging it in a high vacuum environment, thereby removing the moisture from the strawberries. The specific steps are:

- Low-temperature freezing: Pre-treated strawberries are rapidly frozen at -40°C to -50°C, completely converting all their moisture into ice.

- Vacuum sublimation: In a vacuum environment of 30 to 80 Pa, the ice is directly sublimated into water vapor and expelled.

- Drying and forming: After drying, the strawberries retain only 2% to 5% moisture, enabling long-term storage.

This process avoids the high-temperature destruction of nutrients and tissue structure associated with traditional thermal drying, ensuring that freeze-dried strawberries retain virtually unchanged color, aroma, flavor, and shape, while retaining a high degree of nutritional value and exhibiting excellent rehydration properties.

Before entering the freeze dry machine for strawberries, strawberries undergo a series of processes to ensure product quality.

- Sorting and grading: Substandard strawberries are removed to ensure quality.

- Cleaning and disinfection: The strawberries are thoroughly cleaned in a strawberry washing machine to remove surface impurities and pesticide residues.

- Cutting: This step is optional; whole strawberries can be freeze-dried directly, or they can be cut into halves or slices.

- Pre-freezing: The strawberries are pre-cooled to a set temperature to prepare for the subsequent freeze-drying process.

- After these steps, the strawberries are ready for vacuum freeze-drying in the freeze dried machine.

Freeze Dried Machine Features:

- High nutrient retention: Low-temperature drying maximizes the preservation of vitamin C, polyphenols, minerals, and other nutrients in strawberries.

- Excellent product quality: Freeze-dried strawberries retain the natural color, aroma, and shape of fresh fruit, without shrinking, deformation, or discoloration.

- High level of automation: The freeze dry machine for strawberries is equipped with a plc intelligent control system, enabling precise control of parameters such as temperature, vacuum level, and drying time.

- Stainless steel construction: The freeze dried machine is constructed of sus304 food-grade stainless steel, complying with gmp and haccp standards for hygiene and safety.

- Wide application: Suitable not only for freeze-drying strawberries, but also for freeze-drying apples, mangoes, bananas, vegetables, and herbs.

Reviews

There are no reviews yet.