Frozen blueberries are processed using IQF freezer that rapidly lowers the berries’ temperature to below -18°C, causing their internal moisture to crystallize into minute ice crystals. This freezing method minimizes damage to the berries’ cellular structure, preserving their original color, flavor, and nutritional value. Compared to conventional freezing methods, frozen blueberries exhibit minimal juice loss and flavor degradation upon thawing, granting them exceptional market competitiveness.

Frozen Blueberry Machine Features:

- The conveyor belt operates smoothly to preserve blueberry integrity: The tunnel IQF freezer employs a high-strength conveyor belt that runs in a continuous cycle. Its stable operation minimizes excessive compression and friction on the blueberries, ensuring they retain their original shape as much as possible during freezing and preventing deformation or breakage.

- Stepless speed control for flexible adjustment of freezing time: The mesh belt operates with stepless speed control, offering a wide range of adjustable speeds. Users can adjust the belt speed at any time based on the size, moisture content, and final freezing requirements of the blueberries, thereby controlling the freezing duration. This not only enhances production efficiency but also ensures consistent freezing results and stable quality across different batches of blueberries.

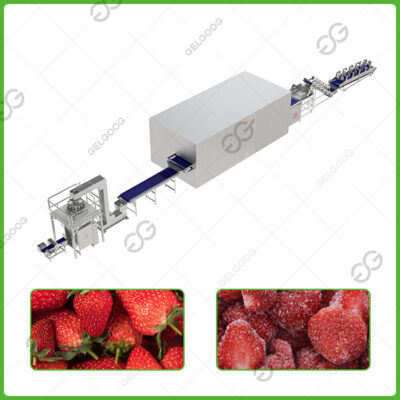

- Wide applicability and strong versatility: In addition to blueberries, this frozen blueberry machine is equally suitable for processing small berries such as strawberries, cherries, and raspberries, as well as vegetables like peas and corn kernels.

When processing with a IQF freezer machine, the following points should also be noted:

- Raw material screening and washing: Before freezing, blueberries must undergo strict selection to remove overripe, damaged, or contaminated fruits. A blueberry washing machine is used to thoroughly clean surface dirt and impurities, ensuring product quality.

- Pre-cooling treatment: Some processing plants briefly pre-cool blueberries before quick-freezing to lower their surface temperature. This reduces the load on the frozen blueberry machine and ensures effective freezing.

- Even layering: Spread blueberries evenly on the conveyor belt, avoiding excessive stacking. This allows cold air to act uniformly on each berry, ensuring consistent freezing.

In addition to IQF freezer machines, we can also provide complete freezing blueberry production lines tailored to customer requirements, encompassing both pre-processing and post-processing stages. Pre-processing equipment includes washers and air dryers to ensure cleanliness and initial treatment of blueberries. Subsequent packaging equipment comprises weighing machines, automatic packaging machines, metal detectors, and cold storage systems, enabling customers to achieve automated production, enhance efficiency, and ensure product safety.

Reviews

There are no reviews yet.