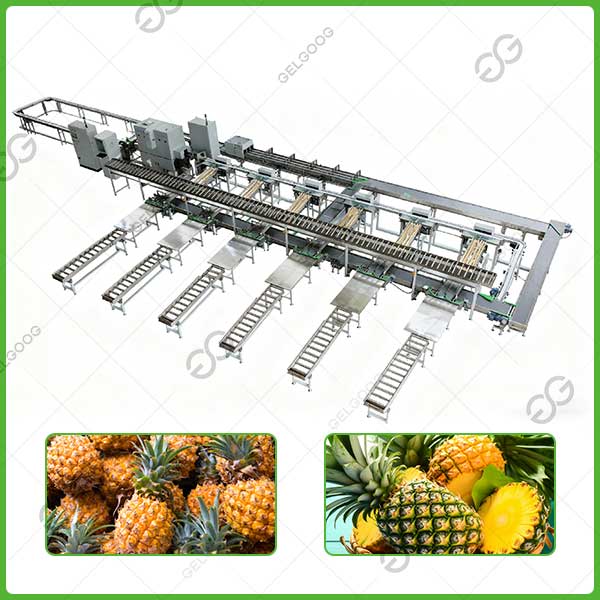

Pineapples vary in shape, size, and color as they grow naturally. Traditional manual sorting is not only inefficient but also subject to subjective factors, making it difficult to guarantee accurate sorting. Therefore, we developed this intelligent automatic pineapple sorting system.

This pineapple sorting machine, independently developed by our company, utilizes advanced AI visual recognition and robotic intelligent control technologies to comprehensively inspect and accurately grade pineapples. The automatic sorting system employing high-definition industrial cameras and multispectral imaging technology, the system comprehensively assesses pineapples based on multiple dimensions, including weight, size, color, shape, defects, sugar content, and lesions.

Pineapple Sorting Machine Features:

- Multi-dimensional detection, high-precision identification: The system utilizes an “AI + machine vision” solution to simultaneously analyze the pineapple’s external characteristics and internal quality. A high-resolution camera and spectrometer work together to accurately identify peel color, surface defects, and sugar content, enabling more scientific grading.

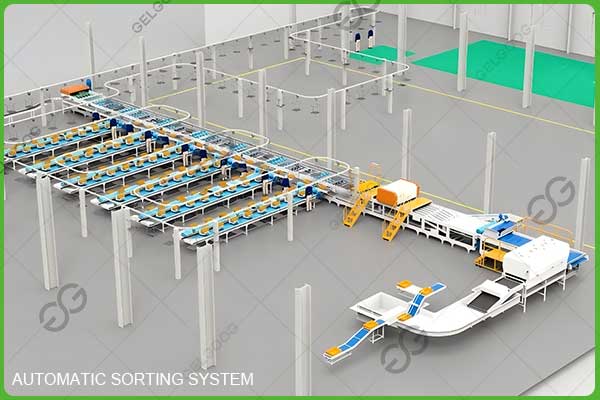

- Modular design and flexible expansion: The pineapple sorting machine adopts a modular design and is divided into functional units such as loading and conveying, positioning and identification, AI detection, automatic sorting, and discharging transmission. The number of sorting channels and production capacity can be flexibly adjusted according to customer needs.

- Energy-efficient and stable operation: The automatic sorting system utilizes a high-efficiency servo motor and intelligent control system, resulting in fast sorting speed, high stability, and easy maintenance.

- Food-grade, safe materials that meet export standards: All parts that come into contact with the pineapples are made of food-grade stainless steel, which is corrosion-resistant and easy to clean.

Fully Automated Pineapple Processing Plant:

The automatic pineapple sorting system can not only operate independently but can also be integrated with other equipment such as cleaning, peeling, dicing, and packaging to form a fully automated pineapple processing production line.

- Washing System: Pineapples undergo high-pressure spray cleaning before grading to remove dirt and impurities, ensuring accurate inspection.

- Packaging System: After sorting, pineapples are automatically weighed and packaged according to grade. Automatic labeling and carton sealing devices can be configured to enable unmanned packaging.

The pineapple processing line boasts a high level of automation, enabling intelligent control throughout the entire process, from raw material intake to finished product shipment. This significantly reduces labor costs, improves processing standardization, and meets the continuous production needs of large and medium-sized pineapple processing plants.

Reviews

There are no reviews yet.